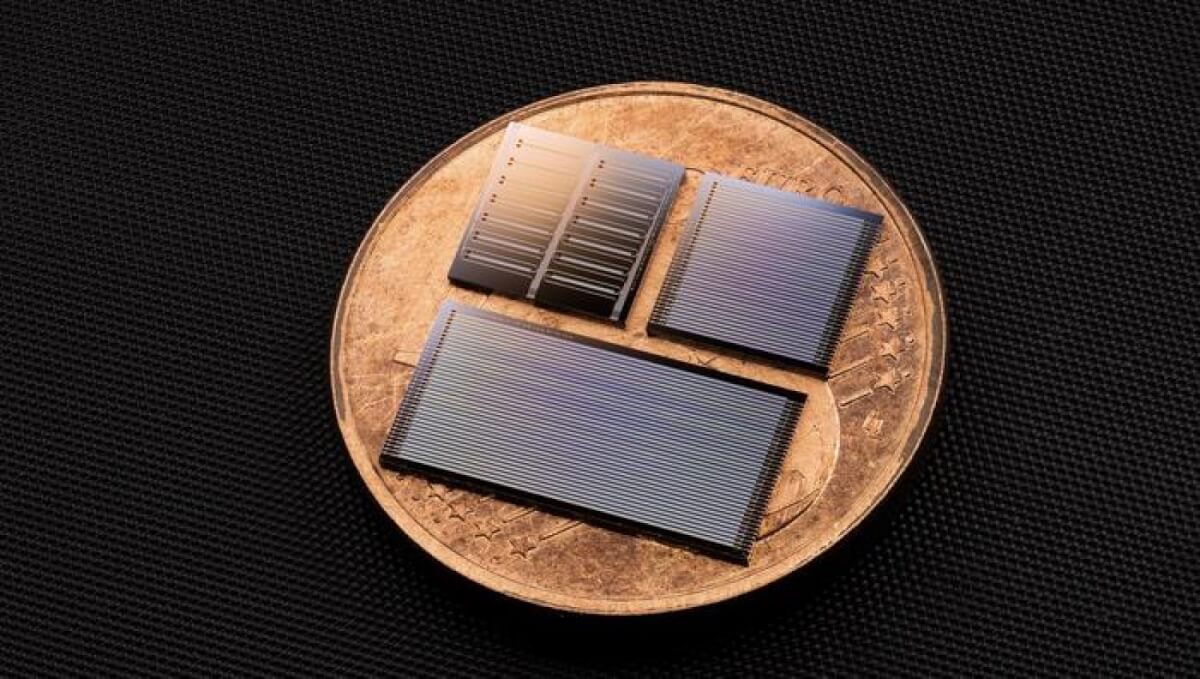

Lithium tantalate photonic integrated circuits. (CREDIT: Tobias Kippenberg (EPFL))

LAUSANNE, Switzerland — In the rapidly evolving world of high-speed optical communications, a critical bottleneck has been the cost and scalability of the specialized materials used to create photonic integrated circuits (PICs). These tiny chips use light instead of electricity to transmit data, enabling blazing-fast internet speeds and powerful computing capabilities. Now, researchers from Switzerland and China have developed a groundbreaking solution using an often-overlooked material: lithium tantalate.

PICs are the unsung heroes of our digital age. They're the backbone of fiber-optic networks, enabling the high-speed internet we rely on for everything from streaming video to cloud computing. They're also critical components in cutting-edge applications like quantum computing and artificial intelligence.

Traditionally, lithium niobate has been the go-to material for PICs. It's a wonder material that efficiently converts electrical signals into light and vice versa, thanks to a property known as the Pockels effect. However, lithium niobate has a major drawback: it's expensive and difficult to manufacture at scale.

Enter lithium tantalate. It's a close cousin of lithium niobate, with a nearly identical crystal structure. But there's a crucial difference: lithium tantalate is already being mass-produced for use in 5G wireless filters. This means that the infrastructure and processes for making lithium tantalate wafers are well-established and cost-effective.

The researchers, led by Dr. Tobias J. Kippenberg at EPFL and Dr. Xin Ou at SIMIT, saw an opportunity. They wondered if they could adapt lithium tantalate for use in PICs, combining its cost advantages with the high-performance properties of lithium niobate.

The first step was to create thin films of lithium tantalate on insulator (LTOI) substrates. They used a process called “smart-cut,” which involves implanting hydrogen ions into a lithium tantalate wafer, bonding it to a silicon wafer, and then heating it until the hydrogen expands and slices off a thin layer. This layer is then polished to the desired thickness, in this case, a mere 600 nanometers.

Next, the researchers needed to etch the LTOI films into the intricate patterns required for PICs. They adapted a process they had previously developed for lithium niobate, using a hard mask made of diamond-like carbon. This allowed them to create smooth, low-loss optical waveguides - the “wires” that guide light through the PIC.

But creating the structures was only half the battle. The researchers also needed to equip the PICs with electrodes to control the flow of light. Here, they innovated again, developing a process using deep-ultraviolet lithography that could create high-quality gold electrodes with precise alignment.

The results, published in the journal Nature, were stunning. The LTOI PICs showed optical losses as low as 5.6 decibels per meter - a key measure of performance. They also demonstrated high-speed electro-optic modulation, with performance comparable to state-of-the-art lithium niobate devices.

But perhaps most exciting was the discovery that lithium tantalate has some unique advantages over lithium niobate. One is its much lower birefringence - a property that can cause unwanted mixing of light polarizations. This means that LTOI PICs can operate over a wider range of wavelengths, covering all the major telecom bands.

Another advantage is lithium tantalate's suitability for generating “soliton microcombs” — ultra-precise frequency combs that could enable even higher data rates in the future. In lithium niobate, soliton generation has been limited by certain crystal orientations. However, the researchers found that by carefully controlling the orientation of their LTOI waveguides, they could generate solitons in any direction.

“While maintaining highly efficient electro-optical performance, we also generated soliton microcomb on this platform,” says Chengli Wang, the study’s first author, in a media release. “These soliton microcombs feature a large number of coherent frequencies and, when combined with electro-optic modulation capabilities, are particularly suitable for applications such as parallel coherent LiDAR and photonic computing.”

This work could have far-reaching consequences. By leveraging the existing manufacturing infrastructure for lithium tantalate, LTOI PICs could be produced at a fraction of the cost of lithium niobate devices. This could make high-speed optical communications more accessible and affordable, both for long-haul networks and for data-hungry applications like data centers and 5G wireless.

However, the benefits go beyond cost. Lithium tantalate's unique properties, like its low birefringence and versatility for soliton generation, could enable entirely new capabilities in PICs. For example, researchers are exploring using PICs for quantum computing, where the ability to precisely control and entangle photons is critical.

This breakthrough in LTOI PICs is a shining example of how materials science, manufacturing innovation, and optical engineering can come together to drive transformative progress. By thinking outside the box and leveraging an overlooked material, these researchers have opened a new frontier in high-speed optics. The future looks bright indeed - and it's illuminated by the power of light on a chip.

EdNews Editor-in-Chief Steve Fink contributed to this report.